Introduction

A Security Operations Center (SOC) is a centralized team responsible for monitoring, detecting, and responding to security incidents. SOCs are typically staffed with security analysts who use a variety of tools and technologies to identify and investigate potential threats.

In the industrial complex, a SOC can play a critical role in protecting critical infrastructure from cyber-attacks. By monitoring and analyzing network traffic, SOC analysts can identify suspicious activity that could indicate a potential attack. SOC analysts can also respond to incidents quickly and effectively, helping to minimize damage.

Challenges Faced for Building Industrial SOC

There are a number of challenges that can be faced when building an industrial SOC. These challenges include:

- The complexity of industrial networks

- The lack of security expertise in the OT industry

- The high cost of security solutions

- The resistance of OT organizations to change

What IEC 62443 tells about SOC

IEC 62443 is an international standard that provides guidance on the security of industrial control systems (ICS). IEC 62443 includes a number of requirements for SOCs, including:

- The SOC must be staffed with experienced security analysts

- The SOC must have access to a variety of security tools and technologies

- The SOC must have a well-defined security plan

- The SOC must be able to respond to security incidents quickly and effectively

Building SOC as per NIST standard

The National Institute of Standards and Technology (NIST) has published a number of standards that can be used to build an effective SOC. These standards include:

- NIST Special Publication 800-53

- NIST Special Publication 800-61

- NIST 800-82

NIST standards provide guidance on a variety of security topics, including:

- Risk management

- Security controls

- Security awareness training

Building an Industrial SOC (Security Operations Center)

In today’s digital landscape, organizations across various industries face increasing cybersecurity threats. The rise of sophisticated attacks targeting industrial control systems (ICS) and operational technology (OT) necessitates robust security measures to protect critical infrastructure. To address these challenges, organizations can establish an Industrial Security Operations Center (SOC). An Industrial SOC is a specialized facility equipped with advanced technologies and skilled personnel to monitor, detect, analyze, and respond to cybersecurity incidents in industrial environments. In this article, we will delve into the key considerations and steps involved in building an Industrial SOC.

1. Understanding the Industrial Threat Landscape

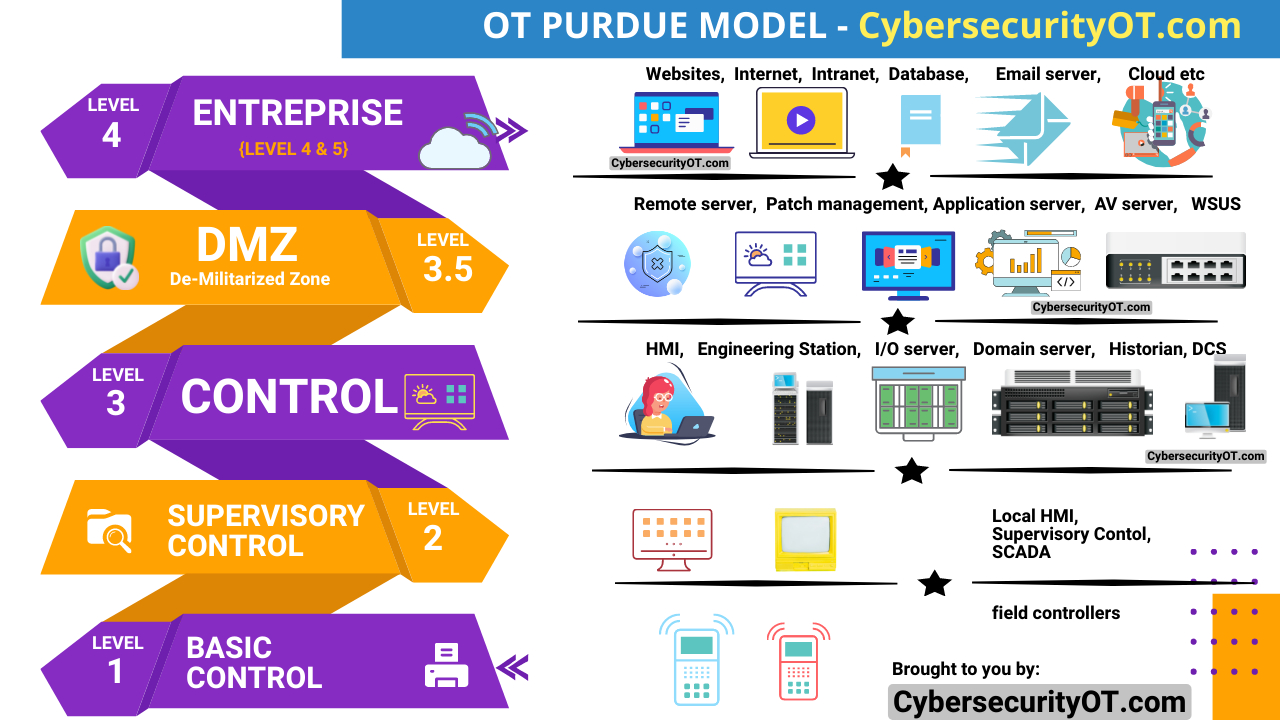

Before embarking on building an Industrial SOC, it is crucial to comprehend the unique threat landscape that industrial organizations face. Industrial control systems, such as Supervisory Control and Data Acquisition (SCADA) systems, Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC), are increasingly connected to corporate networks and the internet. This integration creates potential entry points for attackers to exploit vulnerabilities and gain unauthorized access to critical systems. Some common threats in industrial environments include:

- Malware and Ransomware: Industrial organizations are susceptible to malware and ransomware attacks that can disrupt operations and demand ransom for system restoration.

- Physical Attacks: Physical attacks, such as unauthorized access to industrial facilities, tampering with equipment, or theft of sensitive data, can cause severe disruptions and compromise safety.

- Insider Threats: Disgruntled employees, contractors, or malicious insiders pose a significant risk to industrial organizations. Insider threats can lead to intellectual property theft, sabotage, or unauthorized system access.

- Supply Chain Attacks: Industrial environments rely on a complex network of suppliers and vendors. A compromise in the supply chain can introduce malicious software or hardware, leading to security breaches.

- Legacy System Vulnerabilities: Many industrial systems run on outdated technologies that may have known vulnerabilities, making them attractive targets for attackers.

By understanding these threats, organizations can better design and implement a comprehensive security strategy within their Industrial SOC.

2. Defining the Scope and Objectives

The next step in building an Industrial SOC is defining its scope and objectives. This involves assessing the specific needs and requirements of the organization, considering factors such as industry regulations, the criticality of assets, and the desired level of security. The scope should encompass:

- Asset Inventory: Identify and categorize critical industrial assets, including control systems, network devices, and other connected equipment.

- Network Architecture: Understand the network topology, including connections to external networks and the internet, to identify potential attack vectors and critical control points.

- Data Collection and Logging: Determine what data needs to be collected, such as network traffic logs, system logs, and alerts from security devices, to facilitate effective incident detection and response.

- Compliance Requirements: Consider relevant industry regulations, such as NERC CIP, IEC 62443, or other standards that dictate security practices for industrial environments.

- Incident Response: Define the desired incident response capabilities, including escalation procedures, incident classification, and coordination with external stakeholders such as law enforcement or regulatory bodies.

Clear objectives will guide the selection of appropriate technologies, tools, and personnel for the Industrial SOC.

3. Establishing a Dedicated Team

A crucial component of an Industrial SOC is assembling a skilled and dedicated team capable of handling the unique challenges posed by industrial cybersecurity. The team should consist of individuals with expertise in the following areas:

- Industrial Control Systems: Professionals well-versed in the intricacies of industrial control systems, including SCADA, DCS, PLCs, and other relevant technologies.

- Cybersecurity: Individuals with expertise in cybersecurity, including network security, incident response, vulnerability management, and threat intelligence.

- Physical Security: Personnel knowledgeable in physical security measures and protocols to protect industrial facilities from unauthorized access and tampering.

- Compliance and Regulations: Experts familiar with industry-specific regulations, compliance requirements, and best practices for industrial cybersecurity.

Building a multidisciplinary team with diverse skill sets will ensure comprehensive coverage of security aspects within the Industrial SOC.

4. Infrastructure and Technology

The infrastructure and technology deployed in an Industrial SOC are critical to its effectiveness. Here are key considerations when selecting and implementing the necessary components:

- Network Monitoring: Implement network monitoring solutions capable of capturing and analyzing network traffic within industrial environments. Network Intrusion Detection Systems (IDS) and Network Intrusion Prevention Systems (IPS) can play a crucial role in identifying potential threats.

- Endpoint Protection: Deploy endpoint protection solutions that secure industrial control devices, servers, workstations, and other endpoints from malware, unauthorized access, and tampering.

- Security Information and Event Management (SIEM): Utilize a SIEM platform to aggregate and correlate security events, logs, and alerts from various sources within the industrial environment. SIEM solutions provide centralized visibility and enable efficient incident detection and response.

- Vulnerability Management: Implement a vulnerability management program to regularly assess and remediate vulnerabilities in industrial systems. This includes conducting periodic vulnerability scans, patch management, and configuration audits.

- Identity and Access Management: Enforce strict access controls and implement robust identity and access management (IAM) mechanisms to ensure that only authorized personnel can access critical systems and data.

- Threat Intelligence: Leverage threat intelligence feeds and services to stay updated on the latest threats targeting industrial environments. This information can enhance the Industrial SOC’s ability to detect and respond to emerging threats.

- Physical Security Measures: Implement physical security controls such as surveillance cameras, access control systems, and alarms to protect industrial facilities from unauthorized physical access.

The selection of specific technologies and tools will depend on the organization’s requirements, budget, and the nature of the industrial environment.

5. Incident Response Processes

Establishing robust incident response processes is paramount for the effectiveness of an Industrial SOC. Key elements to consider include:

- Incident Classification: Define a classification scheme to categorize and prioritize incidents based on severity, impact, and urgency.

- Escalation Procedures: Establish clear escalation paths and communication channels for reporting incidents and involving relevant stakeholders, such as IT teams, operations personnel, or executive management.

- Playbooks and Runbooks: Develop incident response playbooks and runbooks that provide step-by-step guidance on how to respond to various types of incidents. These documents should outline procedures, tools, and contact information necessary for effective response and resolution.

- Coordination with External Parties: Define protocols for coordinating with external entities, such as law enforcement agencies or regulatory bodies, in the event of a significant incident or breach.

- Post-Incident Analysis: Conduct thorough post-incident analysis to identify lessons learned, improve response procedures, and update security controls to prevent similar incidents in the future.

Regular testing and tabletop exercises can help validate the effectiveness of incident response processes and identify areas for improvement.

6. Continuous Monitoring and Threat Hunting

An Industrial SOC should adopt a proactive approach to security by implementing continuous monitoring and threat-hunting practices. This involves:

- Real-Time Monitoring: Continuously monitor network traffic, system logs, and security events to detect and respond to potential security incidents promptly. Automated alerting mechanisms can assist in rapid incident identification.

- Threat Hunting: Proactively search for signs of compromise or indicators of advanced persistent threats (APTs) within the industrial environment. Threat hunting involves analyzing historical data, conducting anomaly detection, and employing advanced techniques to identify stealthy threats that may evade traditional security controls.

- Intelligence-Driven Defense: Leverage threat intelligence to inform security decisions and prioritize response efforts. By understanding the tactics, techniques, and procedures (TTPs) employed by threat actors targeting industrial environments, the Industrial SOC can enhance its detection and mitigation capabilities.

Continuous monitoring and threat hunting help ensure early detection of threats and minimize the dwell time of attackers within the industrial infrastructure.

7. Training and Awareness Programs

Human factors play a significant role in industrial cybersecurity. It is crucial to invest in training and awareness programs to educate employees, contractors, and other personnel about their roles and responsibilities in maintaining a secure environment. Key training areas include:

- Cybersecurity Awareness: Educate personnel about common cyber threats, social engineering techniques, phishing attacks, and best practices for maintaining strong passwords and secure behaviors.

- Secure Coding and Configuration: Provide training to developers and system administrators on secure coding practices, secure system configurations, and proper software patch management.

- Incident Reporting: Establish clear channels for reporting potential security incidents, and educate employees on the importance of promptly reporting suspicious activities or events.

- Ongoing Training: Keep security personnel up to date with the latest trends, technologies, and threats through regular training programs, certifications, and knowledge-sharing sessions.

By fostering a culture of security awareness, organizations can significantly enhance their overall security posture.

8. Compliance and Audit

Compliance with industry regulations and conducting regular audits are essential aspects of building and maintaining an effective Industrial SOC. Key considerations include:

- Regulatory Requirements: Familiarize yourself with relevant industry regulations, such as NERC CIP, IEC 62443, or sector-specific guidelines, and ensure that the Industrial SOC aligns with these requirements.

- Periodic Audits: Conduct regular audits of the Industrial SOC’s processes, controls, and technologies to ensure compliance and identify areas for improvement.

- Documentation and Reporting: Maintain thorough documentation of security policies, procedures, incident response activities, and audit findings. Regularly report on the Industrial SOC’s performance and metrics to executive management and relevant stakeholders.

Compliance and audit processes help validate the effectiveness of the Industrial SOC and provide assurance to regulatory bodies and stakeholders.

Conclusion

Building an Industrial SOC is a critical undertaking for organizations operating in industrial environments. By understanding the unique threats, defining clear objectives, assembling a skilled team, implementing robust infrastructure and technologies, and establishing effective incident response processes, organizations can significantly enhance their security posture and protect critical industrial assets. With continuous monitoring, proactive threat hunting, training and awareness programs, and compliance with industry regulations, an Industrial SOC can adapt and respond to the evolving cybersecurity landscape, ensuring the resilience of industrial control systems and operational technology.

Remember, the journey to building an effective Industrial SOC is an ongoing process. Regular assessments, updates, and improvements are necessary to stay ahead of emerging threats and maintain a strong security posture in the face of evolving challenges.